BD Evaporative Cooling

Fresh air supply systems

– the right solution for every type of pig house!

The ideal cooling system for poultry houses in regions with hot and dry summers.

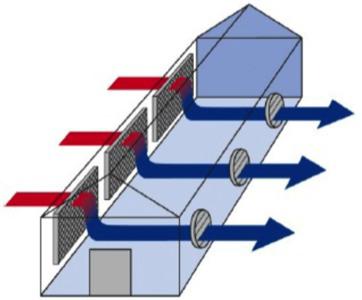

Evaporative cooling system with plastic pads

RainMaker is a cooling system which is mainly used in regions with hot and dry summers. It is based on the evaporation

principle.

Open system means water supply is always visible and allows no closed spaces for rodents to nest

Bottom trough acts as reservoir

Top deflector ensures water is evenly distributed on the whole pad

Easy installation and pads easily removed for maintenance

Water pumped with swimming pool pump

Frame System

RainMaker features an innovative frame system with top profile and pad retainer

Top profile with perforated pipe and deflector for an even distribution of water along the pads

Practical snap-retainers allow for a simple and quick replacement of the pads

RainMaker can be used with conventional cellulose (paper) pads or the new plastic cooling pads.

Cellulose pads are made of a special cellulose material that provides a large surface area for high cooling capacity. Chemical impregnation

protects the pads from the influence of weather

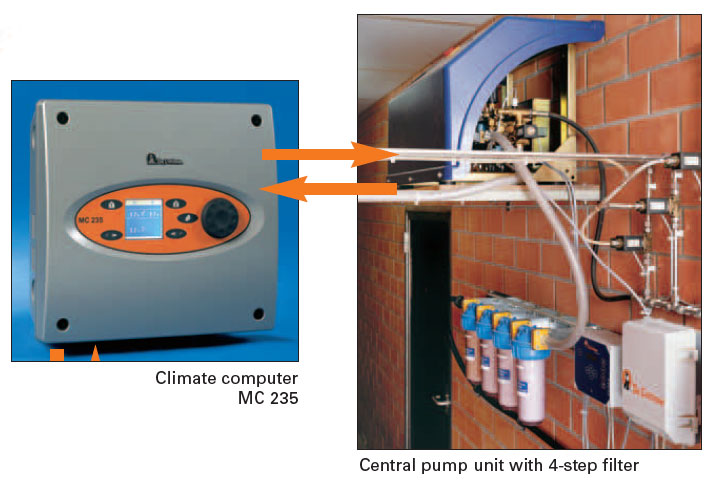

CombiCool effective high-pressure fogging system

CombiCool is a specially designed high-pressure fogging system for cooling, humidifying and wetting the pigs, especially in compartmentalised

houses. The special SST nozzles are characterized by very low passage rates but an extremely high passage speed. This creates a very

fine aerosol fog that is distributed evenly all over the compartment and is immediately absorbed by the hot air and so secures a comfortable

temperature. Furthermore, CombiCool can be used for humidifying the in-house air throughout the whole year providing optimum humidity

conditions.

Mode of operation

If the temperature rises above the preset level, the climate computer MC 235 activates the cooling system. The pump switches on and the

main duct is loaded with a pressure of approximately 60 bar. A high-pressure valve which is installed over every compartment opens

and a fine aerosol fog is sprayed into the space through the nozzles. The multi-step filter unit which is installed in front of the

pump prevents foreign matter from blocking the nozzles.